The restoration of a BMW 1600 GT is like that of a GLAS GT Coupé, or the convertible. Therefore, in this article, it is often referred to the restoration of a GLAS GT convertible. Especially bodywork is remarkably similar. But let us start here as well with the history of the car.

In 2011, Elliot Schnackenberg from the USA purchased the BMW 1600 GT from Sweden through the mediation of friends from Germany. Despite the alleged condition 2, he had the coupé completely restored by restoration company Matejcec in Pilsen, in the Czech Republic. Matejcec was kind enough to provide us with many detailed photographs of the restoration.

The bodywork

As with the GLAS GT Cabrio, it is amazing how much corrosion there is not visible from the outside of the vehicle. The work required on the GLAS GT Cabrio is not brought up again, but you can read about it at https://www.glasclub.de/index.php/de/glas-fahrzeuge/glas-gt/restaurierung?start=1

A-pillar

The A-pillar had been restored before, but you can clearly see here that the rust is still sitting under the sheet metal of the fender.

The whole area was sandblasted and new sheet metal welded in. Then everything was primed.

Often just the whole area around the A-pillar is very dilapidated. In any case during a thorough restoration the outer sheet metal skin should be removed and later re-attached or renewed.

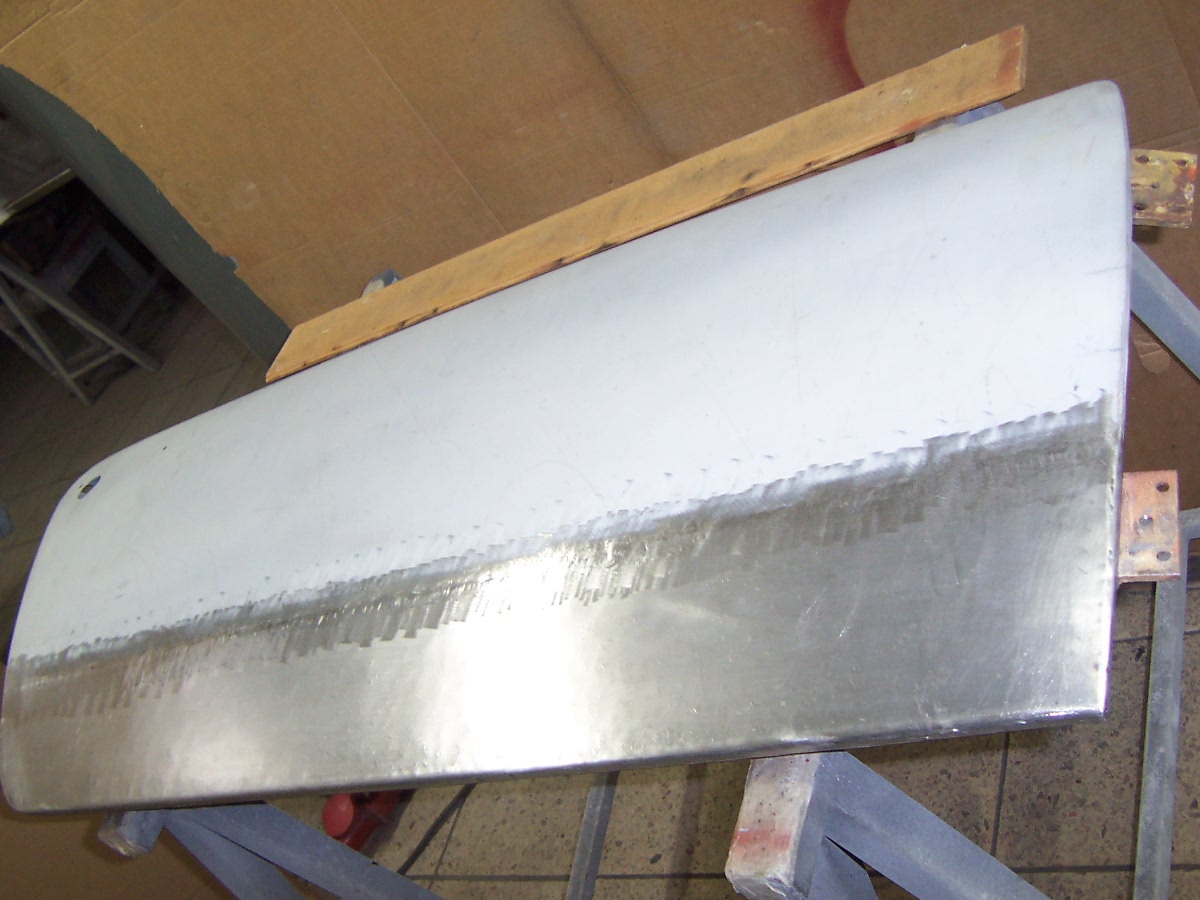

The outer door skins

Water always runs down inside the doors. At the bottom there are drain holes and there are also drain holes in the outer sills.This proofed to be not a highly effective design and after some years it always causes corrosion problems on the sills and doors.

The drain holes in the doors get blocked over time and the water accumulates at the bottom of the doors. Rust then forms and there are hardly any doors that are not rusted through at the bottom edg

Here in this case 10 cm from the bottom edge of the outer door skin were cut off and replaced by a new, fabricated section. Often the bottom of the door must be rebuilt as well.

But sometimes the doors are so bad, or have had damage from an accident, that one tries to find a door in better condition. The problem is that the doors were individually fitted to each vehicle in Italy and the appropriate body number was stamped into each door. If other doors are installed, considerable bodywork modifications must be expected.

Here you can see the renewal of the door bottom. Afterwards everything is sandblasted and primed again.

Then the outer skin is welded on to it. If you have done everything correctly, you should have peace and quiet here for many years.

Rear wheel arches

The rear wheel arches are also often rusted through. Since they are covered with a carpet, it is difficult to notice. They are wider than on the GLAS GT because the semi-trailing arm rear axle needs more space.

There are no reproductions and you must fabricate patches.

Miscellaneous

The body should be examined as closely as possible at all points, as there are different rust nests everywhere. It is helpful to remove paint by a dipping process or to dry ice blasting.

The painting

The front axle

The front axle was almost identical to the GLAS GT. Many parts are the same. Only the rubber bushings for the trailing arms are from the BMW 02 and the upper and lower wishbones are from the BMW GLAS V8. But the rubber bushings are the same.

Especially all the rubber bushings should be replaced, because they are mostly 50 years old and have become hard as stone.

After replacing these parts, the car has a completely different handling characteristic.

These parts are all available at the GLAS Club at moderate prices. But since there are so many there is a fair amount of money involved.

At the lower wishbone you must replace the lower ball joint. Usually the vehicles have been standing for some years and the plastic liner in these joints has disintegrated. Failure to do so will result in a rattle from the axle once you take the car back into operation. The same applies to the upper ball joint and the steering rod ball joints. This also may be the case on the replacement parts if they have been stored for 40 to 50 years!

On the outside of the upper wishbone are two rubber bushing (DU-bearing) on each side, which also should be replaced. In the left picture you can see the parts of one axle half.

On the right side of the brake disc the upper ball joint is shown which is fixed to the wheel spindle carrier. Right beside it is the upper wishbone, in its large hole the upper ball joint is mounted. At the outer end of the upper wishbone are the 4 DU- bearing shown which are pressed into the wishbone. The wishbone is mounted then to the axle with the long rod shown. The DU-bearing is a complex part, using an inner steel spacer surrounded by a rubber jacket. Once installed, the wishbone does not pivot in the rod, but in these DU-bearings.

On the right you see the front stabilizer. It is mounted in 2 rubber sleeves onto the lower wishbones on the outside and with 4 rubber bushings housed in two connecting links (not shown) in the middle to the front axle carrier. These bushing look the same on the outside but have different inside diameters. 20 mm for the stabilizer and an 18 mm for the front axle.

The rear axle

It is a semi-trailing arm rear axle, which was also installed in the BMW 1602 in 1968. It is a completely different design than the rigid axle used on the GLAS GT. Parts are available from the BMW Classic.

The axle is quite robust and mostly you only must change the CV boots of the drive shafts.

If required, wheel bearings can be obtained from any automotive parts store.

The engine

For the engine you can still get all parts from BMW, as far as they fit the BMW 1602. But there are also some specific ones that were only used on the BMW 1600 GT. These parts can only be sourced from used car parts suppliers.

The air filter bellows from BMW are for the BMW 2002ti and their bellow has only three folds. These are too short to be used on the BMW 1600 GT. Here one needs the bellows with four folds. This part is reproduced by a club member.

You can have the radiator overhauled by a specialist with a new core. The club also has still contact to the original manufacturer of the radiator from the 60s. For the GLAS GT and some others, new radiators are still being manufactured. For the BMW 1600 GT radiator they only offer a replacement of the core. The address can be found in the club.

The brake booster is a T50 unit from ATE. A repair requires a specialist which may be hard to find. The club has an address of a shop which can refurbish these units.

The fuse box is a somewhat fragile part. The Phenolic circuit board under the fuses is often charred or damaged.

The GLAS GT used the identical unit. This unit is overhauled with new parts by GLAS Club members.

The bumpers are often scratched, rusted, or dented.A specialist company may be able to repair and re-chrome them.

Otherwise the club had arranged the remanufacturing of highly polished stainless-steel bumpers. The bumpers are made in Vietnam and are cheaper than what it would cost for chrome plating in Germany.

The GLAS Club has tested them for quality and fit. For the front bumper there are different models for BMW GT or for the GLAS GT. The rear bumpers are identical on both cars.

GLAS Club members get a special discount.

From the factory, on the BMW 1600 GT, Talbot Berlin 333 exterior mirrors were mounted on both fenders. These mirrors look sleek, but they are difficult to use in traffic. Therefore, many BMW GT are equipped with the exterior mirrors from the BMW 02 mounted to the doors, or with the mirrors from the GLAS GT, which are mounted to the side window frame.

Which mirror you mount is your choice. Original are the Talbot, which are offered again and again on eBay

The interior

The factory interior uses a good quality black vinyl. In contrast to the GLAS GT, some of the material on the seats and the door panels is partially embossed vinyl. The door panels are often damaged, and the vinyl is torn. The pressboard used on the door cars it usually warped or damaged from water, since rainwater can ran down through the door window shaft. Although a plastic foil on the inside of the door should prevent this but it offered only limited protection.

The door card coverings are no longer available. A car upholsterer shop may be able to repair them or make new ones.

The pressboard door cards were replaced with plywood.

Here in this case the owner had the complete interior redone with real red leather.

The complete carpet set consists of more than 20 pieces, including the pieces used in the trunk.

The headliner uses a thin layer of foam rubber, about 1 cm thick under the outer skin. When the foam gets older, it dissolves, and the headliner starts to sag down.

A new headliner is available to purchase, and you must glue it directly to the roof.

The steering column cover houses the controls for heating and ventilation. These covers are often distorted from direct sun light which makes the operation of the controls extremely hard or outright impossible. Especially the "H" control for heat can break off. The whole part is made of plastic with cast in threaded brass inserts. These can also break off over the years. You can have the cover repaired in the club, or better, you can buy the steering column cover made of cast aluminum, offered by the club. Then forever there will be no longer a problem with this part.