Page 2 of 4

The production start

In 1958, came the moment of truth. Potential customers were beating a path to the dealer's doors. But they had to be put off. There was only sparse information with the vague statement that the wait would be worth it. The dealer however insisted on the imminent delivery, to finally offer the step-up model to the previous Goggomobil.

The factory however was pressed for time, because it had been decided not to offer the car for sale as it was shown earlier. It had been said (and written) that the position of the engine forward of front wheels on a front wheel drive car, would result in an unfavorable load distribution. A poor road handling performance would have been the result. Insiders however doubt the truthfulness of this statement, because it was not technically justifiable.

Since the show car was not a drivable prototype and still required a lot of design, it's more likely that Glas and Dompert, during talks at the IAA, convinced them self to offer a "real car" with a standard drive train, engine up front driving the rear wheels. That is also the version the grandson of the boss heard from his uncle.

The design department was now under pressure. It required night shifts to change and change again the design: the large Goggomobil was given a rear-wheel drive and could boast now to be the only small car of its time with the same drive concept as the far more expensive middle class. The transmission was a fully synchronized 4-speed unit from Getrag, which because of the gear set arrangement had an "upside down" shifting pattern.

A few changes were also made on the outside: the window framing was smaller than in the original model, the front grille was made flatter and now included the two directional indicator lights. The tail lights were enlarged. Since there was enough space to store the spare wheel over the low mounted engine in front, the trunk space increased now to more than 300 liters.

Changes were also made to the interior: Wider armrests disguised now the rear wheel arches and the originally from the Goggomobil Coupe acquired speedometer in the prototype was replaced with a ribbon speedometer, whose hooded upper edge was to prevent unwanted reflections from the windshield. This modern instrument cluster had also integrated rocker switches for lights and wipers. (The idea of using flat rocker switches instead of protruding buttons or knobs was later also adopted by other companies.)

Changes were also made to the interior: Wider armrests disguised now the rear wheel arches and the originally from the Goggomobil Coupe acquired speedometer in the prototype was replaced with a ribbon speedometer, whose hooded upper edge was to prevent unwanted reflections from the windshield. This modern instrument cluster had also integrated rocker switches for lights and wipers. (The idea of using flat rocker switches instead of protruding buttons or knobs was later also adopted by other companies.)In the summer of 1958, when all this frantic work on the various test cars, GLAS finally was convinced that all these new design changes would meet the targeted expectations, they rolled out "twins" (but now 100 kg heavier than originally planned): the "Goggomobil T 600 "(20 hp, 100 km / h) and the "T 700" (30 hp, 110 km / h). The prices were attractive: 4,330 German Marks (T 600) and 4,470 German Marks (T 700), including standard heater - which at that time was certainly not a given.

Sales in the first few months were very encouraging. By year-end 1958 6,740 cars were delivered. The following year, then the annual production actually rose to nearly 25,000 units - a figure which was never reached again.

Unfortunately, not everything which shines is gold!

It had become common knowledge that this Goggomobil was put on the market too soon. It was not nearly as reliable and well put together as its smaller brethren. The first buyers felt like an extension of the Dingolfinger testing department.

The fuel consumption was more than 10 Liters/100 km and the adjustment procedures of the two carburetors overwhelmed many repair shops. But that was probably the lesser evil. The list of complaints was long: Too much heat deformed the motor case and an engine failure was inevitable. And in sharp cornering, it could happen that the low oil pressure light indicated a lack of oil supply. Also the front suspension had its problems resulting in a high tire wear. Although the body was rigid enough, still at the B-pillar paint cracks developed. (Re-bounce from slamming the door). The small radius in the corners of the windshield was creating another problem: after rain, the interior was flooded.

The factory, very accommodating to the deceived feeling customers, reacted in response. The Service Department had its hands full. I can remember that in extreme cases, silently the car was simply taken back.

These were not happy times in the house GLAS. They worked feverishly, trying to get a grip on the "growing pains" and fix the construction defects.

No one is a born master! The station wagon and the S 35 drew attention to the progress.

Apparently at the IAA in 1959, GLAS was ready. They presented a thoroughly revised model in which the defects of body and engine were taken care of. The front suspension was completely redesigned and the sheet metal section of the B-pillar had been strengthened. A voluminous windshield gasket solved the flooding problem. In order to reduce fuel consumption, the two Bing carburetors were replaced with a single Solex downdraft carburetor. The clutch was now much easier to operate.

The progress of development work on the "problem child" could not to be overlooked, and from now on nothing should be reminiscent of the failed production start. The "Large" Goggomobil was renamed to the "Goggomobil Isar". Since it was recognized, however, that the emerging new clientele continued to associate the name "Goggomobil" with the rattling mini 2-stroke car, the name was pushed more and more into the background.

The "Goggomobil" lettering on the fenders was replaced by "Isar". This writing of "Isar" was so stretched, that the attachment points of the older, longer word could be used. Only the winged "G" on the hood was retained. In order to boost sales even more, the prices (now without heater) were decreased by 340 DM just to stay under the psychologically important 4,000 German Mark ceiling.

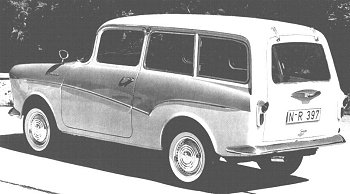

Also at the 1959 IAA, the model family expanded with a station wagon, the K 600 and K 700. At 240 German Marks more, it was more expensive than a comparable sedan. Its extended roof line gave it a more harmonious appearance compared to the sedan and the rear passengers benefitted with more headroom.

Also at the 1959 IAA, the model family expanded with a station wagon, the K 600 and K 700. At 240 German Marks more, it was more expensive than a comparable sedan. Its extended roof line gave it a more harmonious appearance compared to the sedan and the rear passengers benefitted with more headroom.For small businesses it also was offered as a delivery van without the rear seats and rear side windows. Also, an ambulance with retractable stretcher was designed, but never built in series. Also the van could be ordered for 50 German Marks less just primed on the outside. The three-door car had a lift up tailgate which, after folding down the rear seat bench, provided accesses to about 1000 liter of cargo space. His unrivaled payload was 460 kg. The station wagon was available from the beginning and in its time very successful. By 1965 its share of total production was 16.3%. In the last two years of production it was even close to 45%.

To make the public aware of the many improvements, GLAS presented at the same time the Isar S 35 coupe, a Goggo Coupe built on a greatly altered 700 chassis. Since the engine sat in front, this coupe got a new fiberglass front with a large oval air intake reminiscent of the Ferrari Superamerica from 1956. The front bumper was split and now consisted of two short corner pieces. The headlights were from the Isar, the door hinges were sitting in front. The wheel arches were changed for clearance of the 4.80-12 tire size. The narrow rear child seat bench was replaced with a parcel shelf for the benefit of additional storage and the small trunk was now accessible via the former engine lid.

To make the public aware of the many improvements, GLAS presented at the same time the Isar S 35 coupe, a Goggo Coupe built on a greatly altered 700 chassis. Since the engine sat in front, this coupe got a new fiberglass front with a large oval air intake reminiscent of the Ferrari Superamerica from 1956. The front bumper was split and now consisted of two short corner pieces. The headlights were from the Isar, the door hinges were sitting in front. The wheel arches were changed for clearance of the 4.80-12 tire size. The narrow rear child seat bench was replaced with a parcel shelf for the benefit of additional storage and the small trunk was now accessible via the former engine lid.The higher compression engine developed 34 hp at 4,900 RPM (in some publication 5,700 RPM are mentioned) and accelerated from 0 to 100 km/hour in 22 seconds. The top speed was for back then a sensational 135 km/hour. The factory spoke of a "four-stroke boxer sports engine." The first driving tests in the car magazines were encouraging and made the public curious.

The "pocket-sized Ferrari" was to be sold for 4,750 German Marks. But the planned mass production did not happen, because in practice the highly modified motor did not fulfill all of the expectations. Chief designer Dompert commented: "This vehicle was abandoned because of its high noise level and the problems with the fiberglass front section." The S 35 remained a technology showcase for future developments.

To demonstrate the durability of the engine and the robustness of the chassis, the Isar was sent with two engineers on a trip in North Africa through the Libyan Desert. The finish line was reached after more than 1,000 miles without any problem issues the car. One could see the pride of this achievement in the ad: "A proof of performance - down to the last detail!"

The front wheels of the new Goggomobil Isar were individually sprung with coil and progressively acting hollow rubber springs. That was to guarantee, together with the hydraulic shock absorbers and worm and roller steering, a smooth ride.

In a road test (issue 10/1959) about the new Isar wrote Roller, Mobil und Kleinwagen:

"... the progress is undeniable. Although teething trouble and the lack of development are not hereby excused, but we must nevertheless also report that the factory, at high financial effort, took care of all customer claims and that the car which was given to us for this road test, despite the punishing tests ... was really reliable."

As an overall impression it was noted: "First-class handling, economical engine, clever usage of space and exemplary visibility, a very sensible designed and now also well-built car, ....., with some of the good features superior to the competition."